The use of active dry yeast has been widely accepted in the brewing industry as both quality and diversity have been improved considerably in the last decade. In short, the production of active dry yeast starts from a vial with pure liquid culture followed by a series of propagation steps in aerobic fermenters of increasing volume. In the final production fermenter the yeast is grown aerobically. Next the yeast is harvested by centrifugation, concentrated to about 32% dry matter by rotating vacuum filters and dried in a so called fluidized bed dryer in which fast, homogeneous and protective drying is guaranteed. To permit a good resistance to rehydration, the yeast is coated with a protective agent (most times the vegetal emulsifier sorbitan monostearate (MSS)) just prior to drying.

The final powder (see figure 1) consists of 94-97% dry matter and is vacuum-packed to protect against oxidation and moisture and allows preservation of up to 3 years. The long shelf life is one of the major advantages of active dry yeast. In addition, when considering production management there are several other advantages of active dry yeast as a replacement of liquid yeast propagation like e.g. significantly lower costs, no need for yeast quality management (done by supplier) and a massive increase in production flexibility. In comparison with yeast propagation, the preparation time of active dry yeast can almost be neglected. The statement (still circulating on the internet) that propagated yeast has a better fermentation performance and yields better quality beer than active dry yeast has been disproven in several academic studies. Actually, the fermentation and drying processes and related recipes have been designed to best shape-up the yeast in terms of vitality, viability and purity at time of rehydration and fermentation start. Nowadays many high quality and award winning beers are being produced with active dried yeast.

Figure 1: optical microscopy image of active dry yeast powder granules prior to packaging.

To prepare active dry yeast for fermentation, it needs to be rehydrated. The standard rehydration procedure involves the sprinkling of the desired amount of yeast in 10 times its weight in sterile water or hopped wort within a specific optimal temperature range for each yeast and leave to rest for a set amount of time under gentle stirring. Next the yeast cream is pitched in the fermenter.

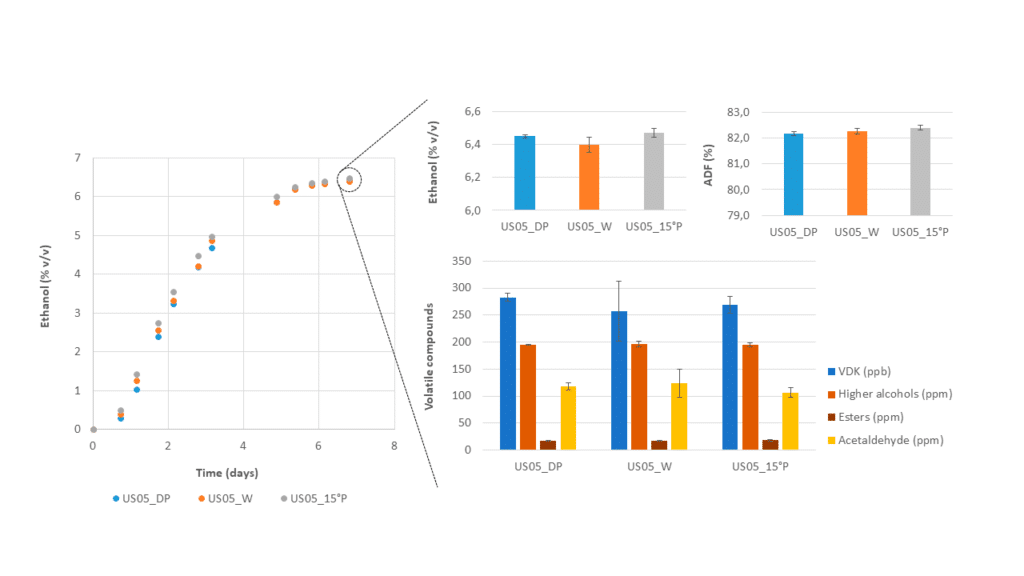

Although this procedure has been proven to be effective, the first results of a new study in which 3 different rehydration procedures, i.e. rehydration at 30°C with moderate agitation, rehydration in 15°P wort at 20°C with moderate agitation and direct pitching without rehydration, indicate no significant differences in fermentation performance for all tested ale yeasts (SafAle™ S-04, SafAle™ US-05, SafAle™ K-97, SafAle™ S-33, SafAle™ WB-06, SafAle™ BE-256, SafAle™ T-58, SafAle™ BE-134) and lager yeasts (SafLager™ S-23, SafLager™ S-189 and SafLager™ W-34/70). At the end of fermentations, no significant differences in concentration of ethanol, residual sugars and volatiles (acetaldehyde, esters, higher alcohols and vicinal diketones) between rehydration procedures were observed (see figure 2). This indicates that the direct pitching procedure is adequate for fermentation.

Figure 2 – Fermentation performance of SafAle™ US-05 (Pitching rate 50 g/hL, 15°P, 20°C) and the concentration of ethanol, residual sugars and volatiles (acetaldehyde, esters, higher alcohols and vicinal diketones) at the end of fermentation for 3 different rehydration procedures (in triplicate).

DP: direct pitching without rehydration.

W: rehydration in water at 30°C with moderate agitation,

15°P: rehydration in 15°P wort at 20°C with moderate agitation

In practice, the consecutive steps for direct pitching are:

- Fill the fermenter with 1/3 of the wort volume (up to the top of the CKT cone) at a temperature of 21-29 °C

- Sprinkle the active dry yeast cells directly in the fermenter

- Add the remaining 2/3 of the volume of wort at fermentation temperature to allow for mixing of yeast and wort.

The new direct pitching procedure further simplifies fermentation in practice as it eliminates the need for rehydration of the active dry yeast prior to the process.