What is ViniLiquid™ and why should you use it?

ViniLiquid™ is still today a highly innovative fermentation activator, developed by Fermentis in order to optimize fermentation performance, especially in the case of poor in nutrient musts. It is a highly degraded autolyzed yeast offering the advantages of both soluble yeast intracellular content and insoluble yeast hulls.

ViniLiquid™’s unique composition helps you improve and secure fermentation thanks to:

- Its strong supply of essential amino acids drastically increasing YAN (Yeast Available Nitrogen) level,

- Its supply in growth and survival factors

- Its detoxification properties and support effect

Its unique liquid formulation makes it easily and directly dispersible into the must, pumpable and safe (no yeast powder inhalation risks). As such, it was our first Easy To Use (E2U™) yeast derivative!

Fermentation improvement using ViniLiquid™

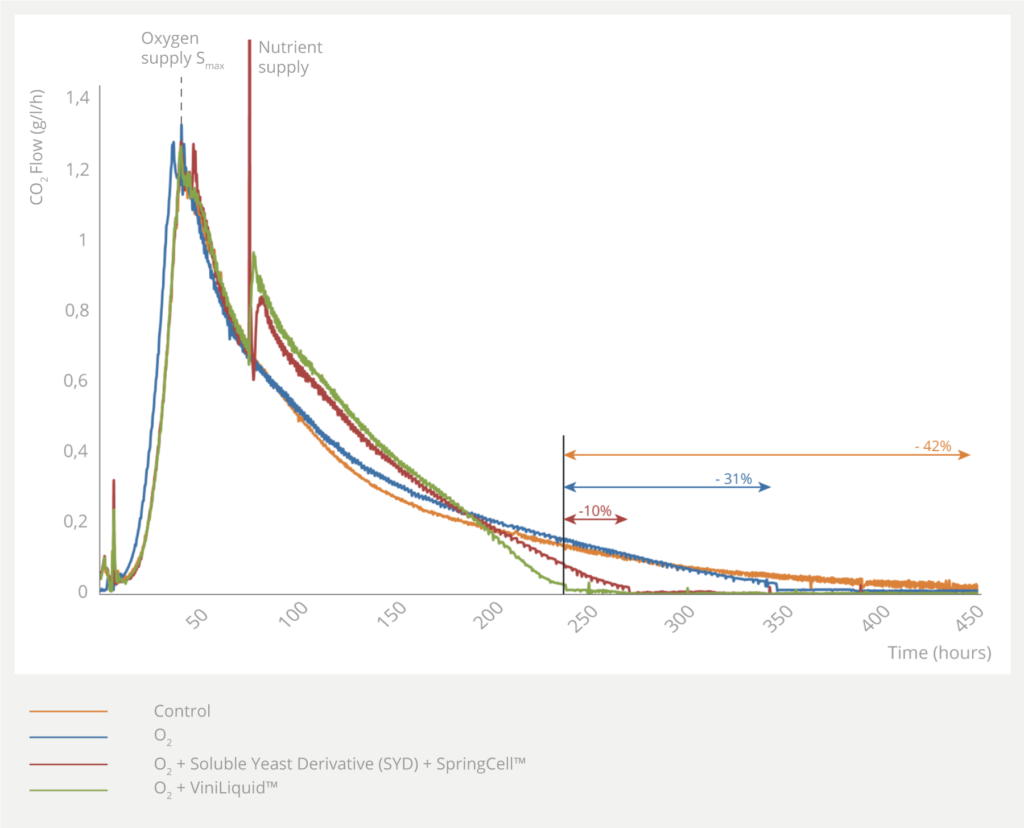

Fermentation times using different activators

Chardonnay must (Potential ABV: 12.5%, pH 3.4 and initial YAN: 188mg/L).

Addition of 10mg/l of O2 at maximum fermentation speed (Smax) then equivalent supply of 20mg/l of YAN and 13.4g/hl of hulls through ViniLiquid™ single addition or mix of soluble yeast derivative and SpringCell™ yeast hulls addition at 1/3rd of the fermentation advancement. Yeast used: SafŒno™ CK S102.

Whilst the addition of O2 alone (blue line) definitely decreases fermentation time, it is clear that adding a mix of yeast derivative and SpringCell™ (red line) is a lot more efficient. But undoubtably, the most efficient way to speed up and secure fermentation is through the addition of O2 and ViniLiquid™, which can decrease fermentation time by up to 42% when compared to the control fermentation. There are strong synergistical effects between O2 and ViniLiquid™ together. However these results show that ViniLiquid™ is more powerful than a dry yeast autolysate with a similar composition, thus reinforcing the point of leaving it liquid.

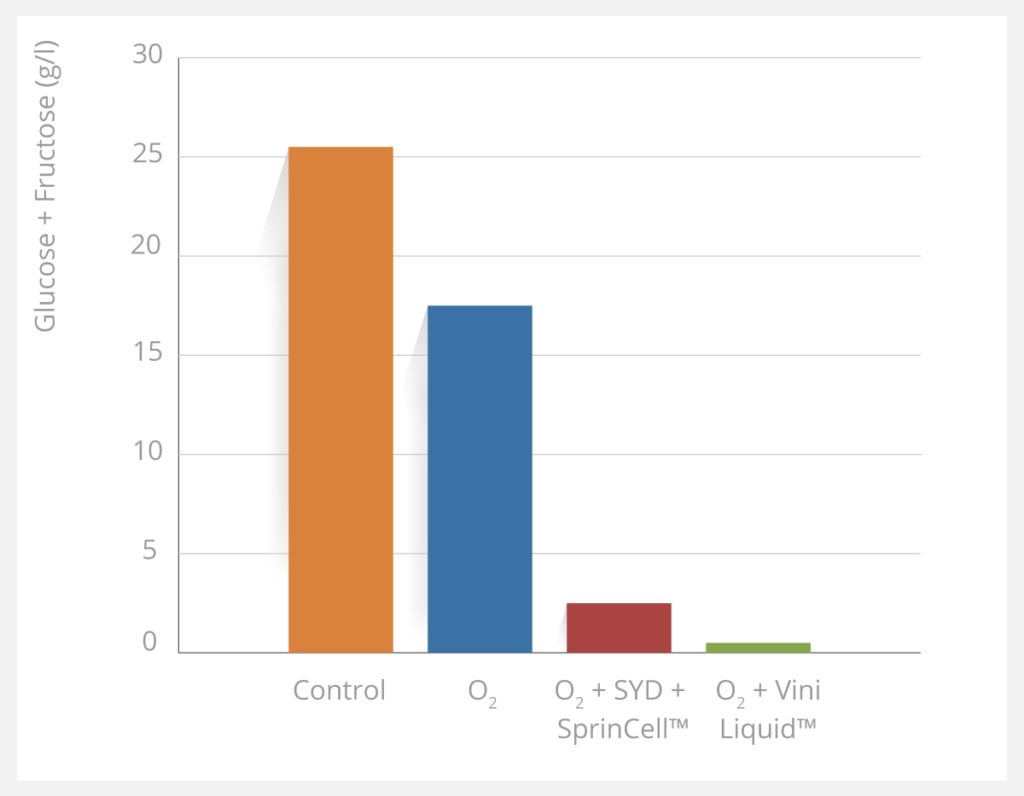

Residual sugars after 238h of fermentation

The graph above shows that after 238h of fermentation, the combination of O2 and ViniLiquid™ led to a fully complete fermentation (0.50g/l of residual sugars) and clearly illustrated that in this must, O2 supply alone was not sufficient to achieve the fermentation whereas the combination with dry yeast derivatives achieved fermentation a bit later.

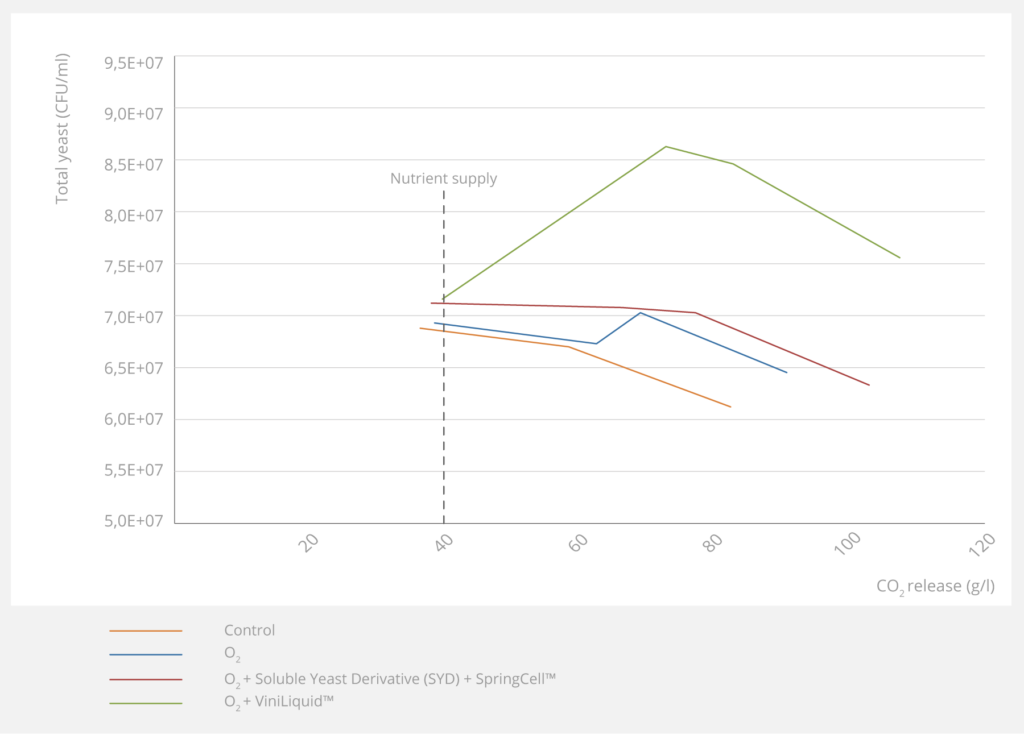

On this yeast viability graph, the addition of nutrients shows an effect on yeast population, with one stand-out winner: ViniLiquid™ which generates a surge in yeast population, whereas other nutrients yield only weak results. ViniLiquid™, like much of Fermentis’ yeast derivative range, is E2U™ certified, meaning it’s very easy and safe to use.

Yeast viability

Gros Manseng must (Potential ABV: 13.5%, pH 3.1 and initial YAN: 115mg/L).10mg/l O2 at Smax, then equivalent supply of 35mg/l of YAN and 19.2g/hl of hulls through ViniLiquid™ single addition or mix of soluble yeast derivative and SpringCell™ yeast hulls addition at 1/3rd of the fermentation advancement. Yeast used: SafŒno™ CK S102.