For fruity sparkling wines

This active dry yeast shows an intense fruity and floral aromatic profile and combines acidity and sweetness while reducing sparkling base wine’s eventual defects (vegetal, bitter). Its orientation towards fruity ethyl esters brings complexity to the wine. SafŒno™ PR 106 is particularly suitable for premium Prosecco bases.

Still white wines: 20 g/hl

Foam setting: 15 to 40 g / hl

Ingredients: yeast (Saccharomyces cerevisiae), emulsifier: (sorbitan monostearate)

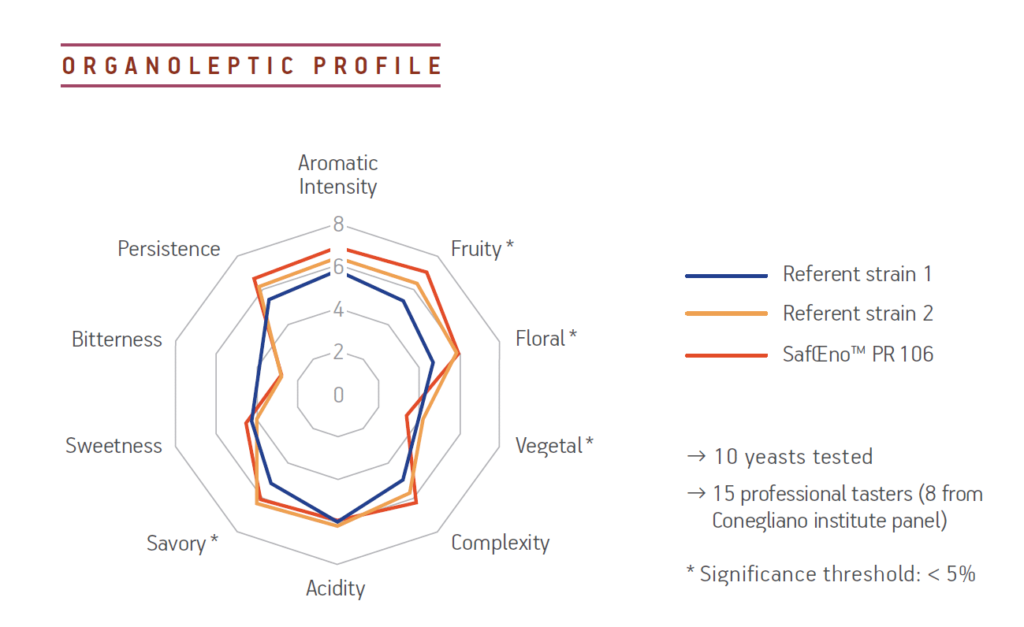

SafŒno™ PR 106 sensory features

For premium Prosecco base wines

SafŒno™ PR 106 exhibits a clean, intensely fruity and floral aromatic profile by producing a high amount of esters and limiting fermentation defects. Its orientation towards fruity ethyl esters brings complexity to the wine while its non-negligible generation of isoamyl acetate can help reduce some vegetal notes sometimes inherent to non-fully ripe grapes. While malic acid consumption and supplying sweetness are not usually desired for these bases, SafŒno™ PR 106 interestingly showed a nice, fresh mouthfeel supported by a pleasant acidity and persistence in the mouth and was locally judged quite positively in regards to Prosecco base wines made of Glera grapes.

For floral and fruity whites, especially terpenic

SafŒno™ PR 106 particularly promotes the release of terpenes and is therefore suitable for fresh and floral terpenic varieties like Muscat. Its balance between amylic and fruity notes is also well adapted to Chardonnay bases, rather grown in warm climates.

Treviso DOC – Glera, 10.4% v / v, pH 3.3, Prosecco base wine.

SafŒno™ PR 106 technical features

Fermentation abilities:

→ Short lag phase and kinetics

→ Recommend temperature range: 10-30°C (50-86°F)

→ Recommended maximum alcohol: 15% vol./vol

→ Low nitrogen requirements: ratio YAN (mg/L) / Sugars (g/L) > 0.7-0.8

→ Good fructose assimilation

Metabolic Characteristics:

→ Medium malic acid consumption (but no acidity loss perception)

→ High SO2 resistance and low SO2 production

→ High production of higher alcohols and esters, especially ethyl esters

→ Favoring a high release of terpenes

Lesaffre know-how and continuous yeast production process improvement lead to obtain an exceptional quality of dry yeasts able to resist to a very wide range of use, cold or no rehydration included, without affecting their viability, kinetic and/or analytical profile. Winemakers can choose usage conditions that fit the best their needs, i.e.:

- Direct inoculation: Pour the yeast on the surface of at least 10 times their weight of must (possibly directly on the top of the tank or during tank filling after settling for whites and rosés). Gently stir to avoid or break clumps. Immediately transfer into the tank via a pumping over with aeration (or homogenize tank volume).

- With prior rehydration: Pour the yeast on the surface of 10 times their weight of tap water at room temperature. Gently stir to avoid or break clumps. Wait for 20 minutes and transfer into the tank via a pumping over with aeration.

Packaging

Carton of 20 vacuum-packed sachets of 500g each (Full box net weight: 10 kg).

Guarantee

The high rate of dry matter of our yeasts assures an optimum storage in its original packaging at a temperature not higher than 20°C (during 3 years) and 10°C for an extended storage (4 years). Fermentis guarantees the product complies with the International Oenological Codex until its Best Before End Date in the storage conditions mentioned above.

Each Fermentis yeast is developed under a specific production scheme and benefits from the know-how of the Lesaffre group, world leader in yeast manufacturing. This guarantees the highest microbiological purity and maximum fermentation activity.

The data contained in this technical sheet are the exact transcription of our knowledge of the product at the mentioned date. They are the exclusive property of Fermentis-Division of S.I.Lesaffre. It is of the user responsibility to make sure that the usage of this particular product complies with the legislation.

Related content

SafŒno™ PR 106 testimonial from Italy

Read this interview about SafŒno PR 106™ from a winemaker specialized in sparkling wine production....

Jul